Production Process

Raw Material

We have always imported High Quality Imported Scrap. There is no compromise in the quality.

Melting

Scrap is charged into a furnace where metal scrap is brought into molten form in order to carry out subsequent steps. The chemical composition of charge is kept according to standards and Grade(G-40 or G-60) quality of steel to be produced.

Intermediate Composition Testing

Continuous samples are drawn from the furnace and chemical composition is tested on spectromax in order to make sure that molten charge is according to standard.

CC Plant

The molten metal is moved to a continuous casting plant where it is brought into an intermediate state known as Billet.

Re-rolling Mill

Next the Billet is moved to Re-rolling mill where it is passed through various mill stations based upon required size to be produced.

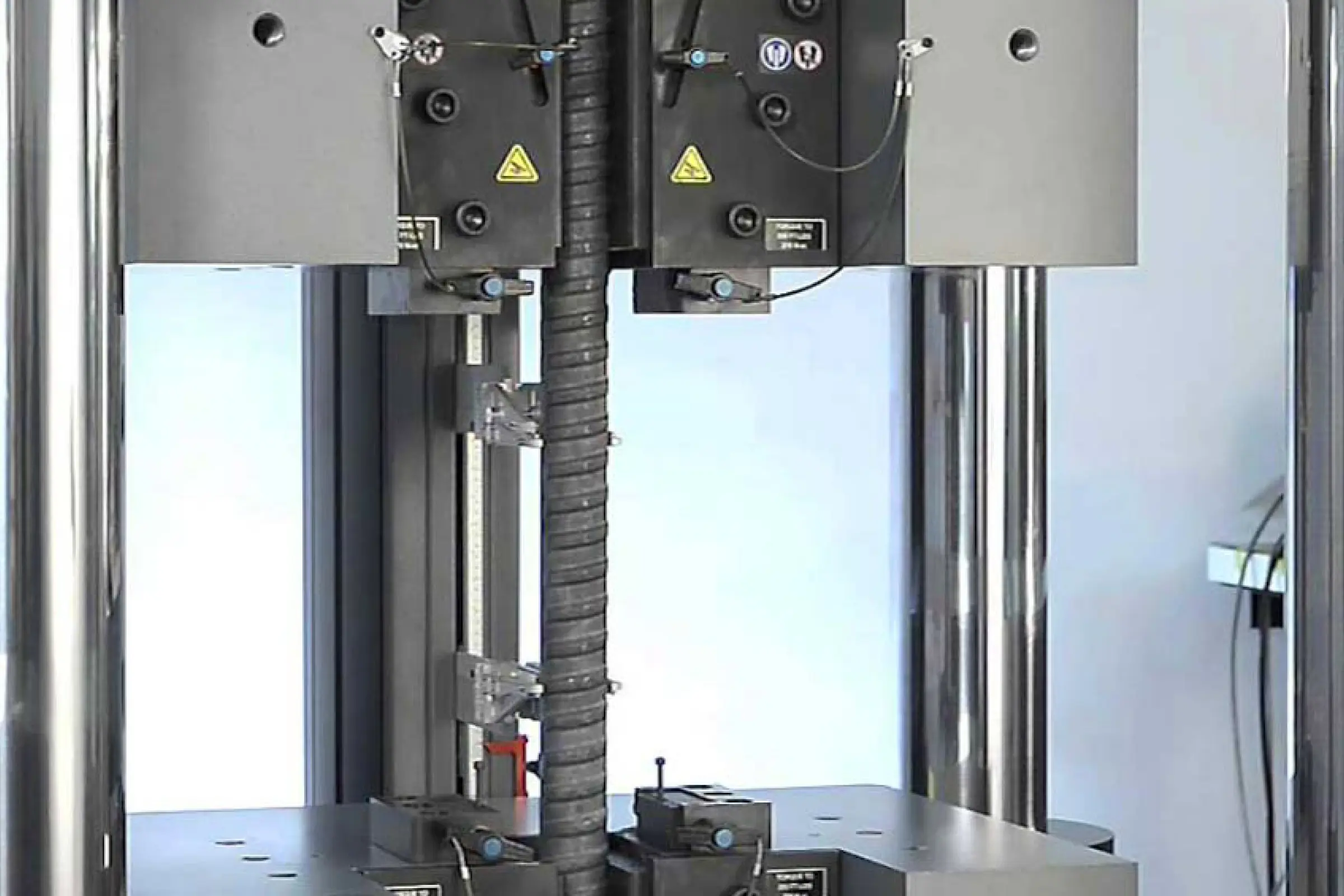

Tensile Testing

A sample is drawn from every batch and is tested on a tensile strength tester where break and bend tests are performed.

Warehousing

The final product is stored in warehouses and is ready to ship.